Introduction

One technology that has revolutionized various industries is Radio Frequency Identification, commonly known as RFID. This innovative system has transformed how businesses track, manage, and secure their assets and inventory. RFID technology has become an indispensable tool for businesses seeking to enhance their operational efficiency and maintain a competitive edge. By leveraging radio waves to identify and track objects, RFID offers a level of automation and accuracy that traditional methods simply cannot match.

From retail giants optimizing their supply chains to healthcare providers ensuring patient safety, RFID technology is making waves across sectors. Its ability to provide real-time data, improve inventory accuracy, and streamline processes has made it a game-changer for businesses of all sizes.

What is RFID?

RFID, or Radio Frequency Identification, is a cutting-edge technology that utilizes electromagnetic fields to automatically identify and track tags attached to objects. This innovative system comprises two main components: RFID tags and RFID readers. The tags, which can be as small as a grain of rice, contain electronically stored information about the item they’re attached to. When these tags come within range of an RFID reader, they transmit this data wirelessly, allowing for quick and efficient identification and tracking.

The beauty of RFID technology lies in its ability to capture information about multiple items simultaneously, without the need for direct line-of-sight or manual scanning. This capability sets it apart from traditional barcode systems, offering unprecedented speed and accuracy in data collection. RFID systems can operate across various frequencies, each suited to different applications and environments, making them incredibly versatile.

One of the key advantages of RFID is its ability to store and transmit more data than traditional barcodes. An RFID tag can contain detailed information about an item, including its origin, manufacturing date, and even its entire journey through the supply chain. This wealth of data enables businesses to gain deeper insights into their inventory and assets, facilitating better decision-making and more efficient operations.

What are the 3 Main Components of an RFID System?

At its core, an RFID system consists of three primary components: RFID tags, RFID readers, and RFID antennas

1. RFID Tag

An RFID tag is the cornerstone of any RFID system, serving as the data carrier that enables object identification and tracking. These small devices consist of two main parts: a microchip that stores and processes information, and an antenna that receives and transmits signals. RFID tags come in various shapes, sizes, and types, each designed to meet specific application requirements.

The microchip in an RFID tag can store a wealth of information about the item it’s attached to. This data can include a unique identifier, product details, manufacturing information, and even historical data about the item’s journey through the supply chain. The amount of data a tag can hold depends on its type and the specific chip used.

2. RFID Antenna

An RFID antenna is a crucial component of the RFID system, serving as the conduit for communication between the RFID reader and the tags. These specialized antennas are designed to transmit and receive radio frequency signals, enabling the seamless exchange of data that is at the heart of RFID technology.

RFID antennas come in various shapes and sizes, each optimized for specific applications and environments. The design of an RFID antenna significantly influences the performance of the entire RFID system, affecting factors such as read range, accuracy, and coverage area

3. RFID Readers

An RFID reader, also known as an interrogator, is a device that emits radio waves and receives signals from RFID tags. It serves as the bridge between the RFID tags and the data processing system, playing a crucial role in capturing and transmitting information in an RFID system

RFID readers come in various forms to suit different applications

- Fixed Readers: These are stationary devices typically mounted in strategic locations such as doorways, conveyor belts, or shelving units. Fixed readers provide continuous monitoring of a specific area and are ideal for applications like inventory management in retail stores or tracking items moving through a supply chain.

- Handheld Readers: These portable devices allow for mobile scanning of RFID tags. They are particularly useful for applications that require flexibility, such as conducting inventory counts in a warehouse or locating specific items in a large store.

- Integrated Readers: These combine the reader and antenna in a single unit, often used in compact or mobile applications.

- Vehicle-Mounted Readers: Designed for use on forklifts or other vehicles in warehouse environments, these readers can automatically track items as they are moved around a facility.

Types of RFID Frequencies

RFID systems operate across various frequency ranges, each with its own characteristics and suitable applications. Understanding these different frequencies is crucial for selecting the right RFID solution for a specific use case. The three main types of RFID frequencies are

Low Frequency (LF) RFID

- Frequency Range: 125 – 134 kHz

- Read Range: Up to 10 cm

- Characteristics:

- Slow data transfer rate

- Less susceptible to interference from metals and liquids

- Higher power requirement

- Applications:

- Access control

- Animal tracking

- Car immobilizers

High Frequency (HF) RFID

- Frequency Range: 13.56 MHz

- Read Range: Up to 1 meter

- Characteristics:

- Faster data transfer than LF

- Moderate susceptibility to interference

- Used in Near Field Communication (NFC) technology

- Applications:

- Smart cards

- Library book tracking

- Payment systems

- Product authentication

Ultra-High Frequency (UHF) RFID

- Frequency Range: 860 – 960 MHz

- Read Range: Up to 12 meters (passive tags), 100+ meters (active tags)

- Characteristics:

- Fastest data transfer rate

- Longest read range

- More susceptible to interference from metals and liquids

- Applications:

- Supply chain management

- Inventory tracking

- Asset management

- Retail item-level tagging

Difference Between Passive and Active RFID

RFID systems can be broadly categorized into two main types based on the power source of the tags: Passive RFID and Active RFID. Each type has its own set of characteristics, advantages, and suitable applications. Understanding the differences between these two types is crucial for selecting the right RFID solution for a specific use case.

Feature |

Passive RFID |

Active RFID |

|---|---|---|

|

Power Source |

No internal power | Internal battery |

| Read Range | Short to medium (up to 10m) | Long (100m+) |

| Tag Size | Small | Larger. |

| Life Span | Very long | Limited by battery |

| Cost | Low (Range $0.20 to $2) | Higher (Range $3 to $20) |

| Data Storage | Limited | Large Capacity. |

| Signal Strength | Weak | Strong |

| Ideal use | High volume and short range | Low volume and long range |

RFID vs NFC - The Key Differences

While RFID and NFC (Near Field Communication) are related technologies that both use radio frequency for communication, they have distinct characteristics and applications. RFID is a broader technology that encompasses various frequency ranges and has a wide array of applications. While, NFC is a specialized subset of RFID technology, operating at a specific high frequency and designed for short-range, two-way communication.

Understanding the differences and similarities between RFID and NFC is crucial for choosing the right technology for a specific use case.

Feature | RFID | NFC |

|---|---|---|

Frequency Range | LF, HF, UHF | HF Only ( 13.56 MHZ) |

| Read Range | Few cm to 100+m | Up to 4 cm |

| Data Transfer | Typically One Way | Two Way |

| Power Source | Passive or active | usually passive |

| Tag Cost | Chep for higher volume | Higher |

| Reader Cost | Higher | Lower. |

| Simultaneous Reads | Yes | Limited |

| Security | Varies by implementation | Built-in security features |

| Consumer Device Integration | Limited | Wide spread in smartphones |

RFID vs Barcode - The Key Differences

RFID and barcode technologies are both widely used for identification and tracking in various industries. Barcodes are optical, machine-readable representations of data, typically used for product identification. RFID uses radio waves to identify and track tags attached to objects. While they serve similar purposes, they have distinct characteristics that make them suitable for different applications. Understanding the differences between RFID and barcode systems is crucial for choosing the right technology for specific business needs.

Feature | Barcode | RFID |

|---|---|---|

Read Method | Optical | Radio frequency |

| Line of Sight | Required | Not required |

| Read Range | Close proximity | Few cm to 100+m |

| Data Capacity | Limited | Larger |

| Read Speed | One at a time | Multiple simultaneously |

| Durability | Can be easily damaged | More durable |

| Cost | Very low | Higher |

| Data Modification | Not possible | Possible (some tags) |

| Security | Limited | More secure options |

| Environmental Sensitivity | Affected by dirt, damage | Less affected |

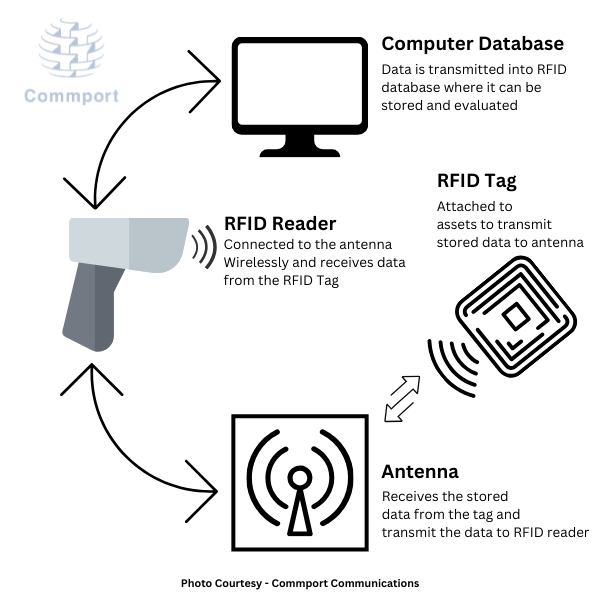

How does RFID work?

RFID technology operates on the principle of using radio waves to communicate between a tag and a reader. This wireless communication allows for the automatic identification and tracking of tagged items without the need for direct line-of-sight. Understanding the mechanics of how RFID works is crucial for appreciating its capabilities and implementing effective RFID solutions.

Basic Components of an RFID System:

- RFID Tag: Consists of a microchip and an antenna

- RFID Reader: Emits radio waves and receives signals from tags

- RFID Antenna: Connected to the reader, transmits and receives radio signals

- Host System: Processes and manages the data collected by the reader

The RFID Communication Process:

- Tag Activation:

- The RFID reader emits radio waves via its antenna.

- When a tag enters the reader’s field, it becomes activated.

- For passive tags, this signal provides the power needed to operate the tag’s chip.

- Data Transmission:

- The activated tag’s chip modulates the reader’s signal with its stored data.

- This modulated signal is reflected back to the reader’s antenna.

- Signal Reception:

- The reader’s antenna receives the modulated signal from the tag.

- The reader decodes this signal to extract the tag’s data.

- Data Processing:

- The reader sends the decoded data to the host system.

- The host system processes and stores the information, often integrating it with other business systems.

What is RFID Used For?

RFID (Radio Frequency Identification) technology is widely used across various industries for tracking, identification, and data collection purposes. The ability to wirelessly read and store data makes RFID a versatile tool in modern business operations. Some of the key use cases include:

- Asset Tracking: RFID enables businesses to track high-value assets in real-time, reducing losses and improving efficiency.

- Access Control & Security: Many companies use RFID for employee ID badges, secure building access, and even payment systems.

- Inventory Management: RFID tags are used to track stock levels and movement, reducing manual errors and increasing visibility.

- Healthcare & Pharmaceuticals: Hospitals and pharmacies use RFID for tracking patient records, managing medications, and preventing counterfeit drugs.

- Logistics & Supply Chain: RFID optimizes warehouse management, shipping, and distribution by providing accurate, real-time tracking of goods.

- Retail Industry: Retailers use RFID to streamline checkout processes, prevent theft, and enhance the customer experience.

How RFID is Used in Retail, Healthcare, Manufacturing, Inventory Management, Logistics, and Supply Chain Management

1. Retail Industry

Retailers utilize RFID to enhance the shopping experience and streamline operations. RFID tags embedded in products allow for quick scanning at checkout, reducing queues. Additionally, retailers can track inventory in real-time, reducing stockouts and improving supply chain efficiency. Major brands like Zara and Walmart have implemented RFID for seamless operations and theft prevention.

2. Healthcare Industry

In healthcare, RFID is used for tracking medical equipment, patient records, and medication administration. Hospitals use RFID wristbands for patient identification, ensuring proper treatment and reducing errors. It also aids in tracking pharmaceutical shipments to prevent counterfeiting.

3. Manufacturing Industry

Manufacturers use RFID to enhance production efficiency and monitor the supply chain. By embedding RFID in raw materials and finished goods, companies can automate inventory tracking and improve quality control processes.

4. Inventory Management

RFID tags help companies automate stock replenishment, monitor product movement, and reduce discrepancies in inventory levels. This is particularly beneficial for warehouses and fulfillment centers, reducing labor costs and human errors.

5. Logistics & Supply Chain Management

Logistics companies utilize RFID for shipment tracking, warehouse automation, and fleet management. RFID technology allows companies to monitor goods in transit, optimize routes, and reduce transit times. It enhances supply chain visibility and reduces losses due to misplacement or theft.

Why Should Suppliers Care About RFID?

Suppliers need to adapt to RFID technology due to the growing demand from retailers and logistics companies. Many major retailers, including Walmart and Amazon, mandate the use of RFID for better inventory control. By integrating RFID, suppliers can:

- Improve supply chain transparency and reduce shipment errors.

- Automate data capture, reducing manual labor and paperwork.

- Meet retailer compliance requirements and avoid penalties.

- Enhance warehouse efficiency with real-time tracking.

- Reduce losses from misplaced or stolen inventory.

What are the Benefits of Integrating RFID?

Integrating RFID into business operations provides numerous advantages, including:

- Improved Efficiency: Automation reduces human intervention and speeds up processes.

- Enhanced Inventory Accuracy: Real-time stock updates minimize discrepancies and improve decision-making.

- Reduced Labor Costs: Automating tracking and scanning reduces the need for manual inventory checks.

- Better Customer Experience: Faster checkouts and accurate product availability improve shopping experiences.

- Compliance & Security: RFID helps businesses meet compliance standards and prevent counterfeiting.

How Does EDI Help Transmit RFID Data?

Electronic Data Interchange (EDI) plays a crucial role in transmitting RFID data efficiently across business networks. When RFID systems collect real-time data, EDI solutions enable seamless communication between suppliers, manufacturers, and retailers by:

- Standardizing RFID-generated data into structured formats like ANSI X12 and EDIFACT.

- Automating order processing, inventory updates, and shipment tracking.

- Enhancing data security by encrypting RFID data during transmission.

- Reducing delays by ensuring real-time updates between supply chain partners.

Advantages of Embedding RFID Technology Within EDI Solutions

Combining RFID with EDI creates a powerful synergy for supply chain management. Some of the major benefits include:

- Automated Data Exchange: Eliminates manual data entry and reduces errors.

- Enhanced Visibility: Provides real-time tracking of shipments and inventory.

- Faster Order Fulfillment: Streamlines communication between suppliers and retailers.

- Better Compliance: Ensures regulatory adherence with accurate reporting.

- Cost Savings: Reduces operational costs by improving workflow efficiency.

Conclusion

RFID technology has revolutionized various industries, enhancing efficiency and accuracy in business operations. From retail and healthcare to logistics and manufacturing, RFID provides real-time visibility and automation. Integrating RFID with EDI further enhances supply chain efficiency, ensuring seamless communication and data exchange. As businesses strive to improve operations and meet market demands, adopting RFID-enabled EDI solutions is essential for staying competitive.

Commport Hybrid B2B Integration Solutions

Frequently Asked Questions

EDI helps transmit RFID data by standardizing the information and automating its exchange between businesses, ensuring seamless inventory updates and order processing.

The cost of RFID implementation varies based on the type of RFID system, the number of tags and readers required, and integration with existing systems. However, the long-term benefits often outweigh the initial investment.

RFID enhances supply chain visibility by tracking inventory in real time, reducing errors, improving efficiency, and ensuring accurate order fulfillment.

Unlike barcodes, RFID does not require direct line-of-sight scanning. RFID tags can be read wirelessly from a distance, while barcodes require physical scanning for each item.

There are three types of RFID tags: passive (no battery), active (battery-powered with longer range), and semi-passive (battery-assisted but relies on a reader to transmit signals).