Introduction

Implementation: 4 Steps to Successful Supply Chain Analytics Implementation

Step1: Understand the Business Case

Before implementing new technology, it’s essential to understand why you need one. To do so, you’ll need to answer two questions: What problem does the technology solve? And what will it cost to implement?

Step 2: Build an Effective Dashboard

A dashboard is a visual display of data that helps you make decisions quickly. It’s also a good place to keep track of trends and patterns. To build an effective dashboard, you need to identify what data you’ll need to collect and how often you’ll need to update it.

Step 3: Develop a Strategy

Once you’ve identified the data you’ll need to monitor, develop a strategy for collecting it. You should consider the following questions when developing your strategy: What will you use the data for? How frequently will you need to access it? Who will be responsible for maintaining it?

Step 4: Execute the Plan

After you’ve developed your plan, execute it. This means making sure you’re able to collect the data you need, as well as ensuring that you have the right tools to analyze it.

Measure Performance: How to Measure the Performance of Your Supply Chain

Understand the Importance of Data Quality

One of the biggest challenges facing organizations today is data quality. It’s not just a problem with big data; even small amounts of bad data can cause significant issues. To avoid these problems, organizations need to ensure that their data is accurate, complete, timely, and relevant.

Determine Which Metrics Matter Most

There are three main metrics that matter when measuring the performance of a supply chain: cost, efficiency, and customer satisfaction. Cost refers to the total price paid by an organization for goods and services. Efficiency refers to the ability of an organization to produce products at the lowest possible cost per unit. Customer satisfaction refers to whether customers are satisfied with the service provided by an organization.

Identify Key Drivers of Performance

To measure the performance of a supply network, organizations need to identify key drivers of performance. These drivers can vary based on the type of business being measured. For example, in manufacturing, the key driver might be the number of units produced per hour; in retail, the key driver might instead be the average order value per transaction. Once these drivers are identified, organizations should then determine what data will help them measure each one.

Supply Chain KPIs & Metrics

Download Free Guide

Top 30 Supply Chain KPIs Your Business Should Be Tracking & Measuring

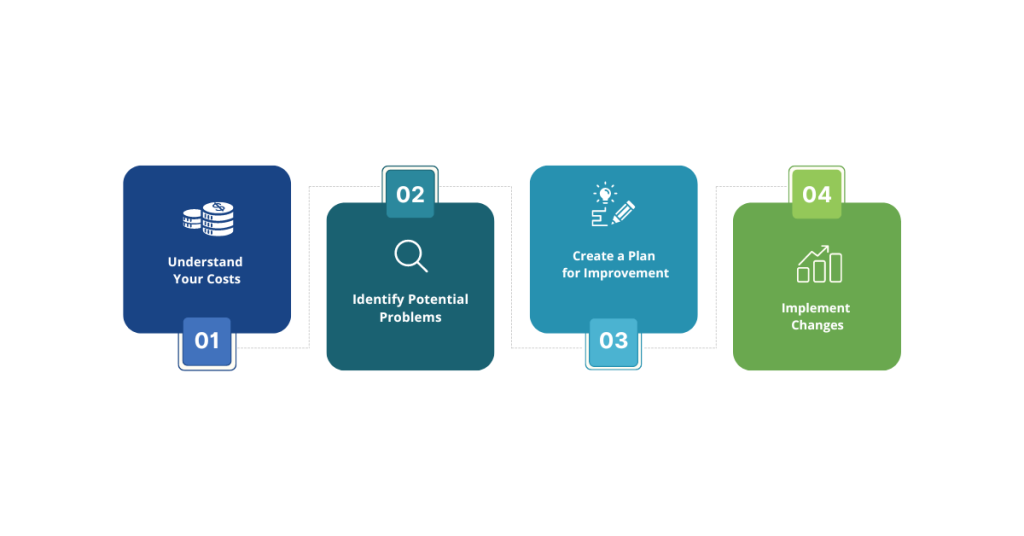

Improve Efficiency: 4 Steps to Improve the Efficiency of Your Supply Chain

Understand Your Costs

To make informed decisions about improving your supply chain, you need to understand what each component costs. This includes everything from the price of raw materials to the cost of shipping. You also need to consider the impact of changes to these variables on your bottom line.

Identify Potential Problems

One of the first steps towards improving efficiency is identifying potential problems. If you notice that one part of your supply chain is taking longer than expected, then you should investigate why. Is there something wrong with the process? Are there any bottlenecks? Do you need to add additional capacity?

Create A Plan for Improvement

Once you identify the problem, you can develop a plan to fix it. You might decide to hire an outside consultant to help you analyze the situation and make recommendations. Or you might decide to implement some changes yourself. Either way, you will need to gather data and assess the impact of each option before making a final decision.

Implement Changes

There are several ways to improve the efficiency of your supply chain. One of the easiest ways is to reduce costs by using less expensive materials. Another way is to use automation to speed up processes. And finally, you can try to find new suppliers who offer better prices.

Ready to find out more Commport Supply Chain Analytics Solution?

Frequently Asked Questions

To implement efficiency, start by mapping your supply chain processes, adopting technology solutions like EDI, optimizing inventory management, and fostering collaboration with suppliers and partners.

Key metrics to measure supply chain efficiency include inventory turnover, order fulfillment cycle time, on-time delivery, lead time, and perfect order fulfillment. These metrics provide insights into different aspects of your supply chain performance.

Yes, technology, such as EDI, can significantly improve supply chain efficiency by automating processes, reducing errors, enhancing communication with trading partners, and providing real-time visibility into the entire supply chain.

Regular assessments are crucial. Depending on your business needs and industry dynamics, consider conducting assessments quarterly, semi-annually, or annually. Regular measurement allows for timely identification of inefficiencies and adjustments to enhance overall performance.

Continuous improvement strategies include adopting emerging technologies, staying informed about industry trends, seeking feedback from stakeholders, fostering a culture of innovation, and regularly reviewing and optimizing supply chain processes for increased efficiency.