Introduction

Did you know that implementing an Advanced Shipping Notice can reduce receiving costs by up to 40%?

This electronic document cuts costs and provides detailed information about incoming shipments. It tracks everything from order numbers to expected delivery dates, which helps businesses streamline their receiving process and manage inventory better.

Supply chain managers face persistent challenges – shipping delays, inventory discrepancies, and warehouse inefficiencies plague daily operations. ASN addresses these pain points through automated document exchange, providing crucial details from order numbers to expected delivery dates.

The business value of ASN extends beyond cost savings:

- Faster unloading operations

- Strategic space management

- Enhanced inventory accuracy

- Automated documentation

- Improved supplier relationships

Many companies still struggle with shipping delays, inventory mismatches, and inefficient warehouse operations. Advanced Shipping Notice (ASN) has become a significant tool for modern supply chains. It enables faster unloading, better space management, and improved accuracy through automated document exchange.

Let’s explore how ASNs can optimize your supply chain! You’ll learn everything from simple components to implementation strategies that can reshape your shipping operations.

Key Takeaways

Operational Efficiency Through Advanced Notification

ASNs can reduce receiving costs by up to 40% by providing detailed shipment information before goods arrive. This advanced notification enables warehouse teams to verify contents, allocate space, schedule equipment, and optimize staff resources, transforming receiving operations from reactive to proactive.Critical Supply Chain Visibility and Coordination

Acting as a digital handshake between trading partners, ASNs bridge communication gaps with standardized electronic formats (EDI 856 or DESADV). This creates unified data flow that enables real-time shipment tracking, precise inventory updates, and strategically timed cross-docking operations.Enhanced Inventory Management and Accuracy

By providing detailed item descriptions, quantities, and packaging specifications ahead of delivery, ASNs enable businesses to make strategic stock-level adjustments. This precision prevents both stockouts and excess inventory while facilitating demand forecasting and efficient space utilization.Serial Shipping Container Codes (SSCCs) Integration

The 18-digit SSCC functions as a digital license plate, connecting physical shipments to electronic documentation. This integration enables automated receiving processes, enhances tracking capabilities, and allows complete shipment details to be retrieved with a single barcode scan.Seamless Trading Partner Relationships

Many distribution centers enforce strict ASN compliance, rejecting shipments without proper documentation. For suppliers, automated ASN processing creates electronic audit trails that expedite insurance claims, resolve disputes, and strengthen buyer relationships through transparent, proactive communication.

Define Advance Shipping Notice (ASN)

Advance shipping notice ASNs work as anticipatory documents and give complete details about upcoming deliveries. The electronic notification has significant information about item descriptions, quantities, carrier details, and expected delivery times.

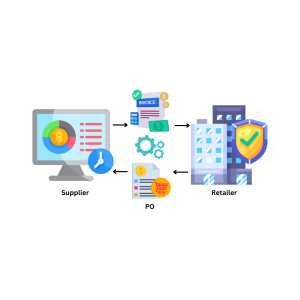

Suppliers send advance shipping notices (ASN) electronically to buyers before shipments leave the warehouse.

The document appears in two primary formats – EDI 856 for X12 systems and DESADV (Dispatch Advice) for EDIFACT standards.

ASNs act as a digital handshake between trading partners, ensuring that all parties in the supply chain are on the same page regarding incoming deliveries.

ASN delivers time-sensitive shipment information before goods arrive at their destination. The document contains:

- Item descriptions and quantities

- Carrier information

- Expected delivery schedules

- Packaging specifications

Unlike traditional bills of lading that accompany shipments, ASN reaches receiving operations ahead of delivery. This early notification empowers warehouse teams to:

Operational Planning

- Verify shipment contents

- Allocate warehouse space

- Schedule equipment and staff

- Monitor inventory levels

ASN strengthens inventory management through strategic stock level adjustments and precise forecasting capabilities. The standardized EDI format ensures reliable data exchange between business partners.

History and Usage of Advance Shipping Notice

The concept of advance shipping notices emerged alongside the adoption of EDI in the late 20th century. Businesses sought ways to improve visibility and streamline inventory management in an increasingly globalized economy.

Initially, ASNs were primarily used by large retailers and manufacturers. Today, however, they are widely used across industries, including eCommerce, automotive, and healthcare. ASNs facilitate better supply chain planning and operational efficiency, making them a cornerstone of modern logistics.

Supply chain operations once relied entirely on physical documentation. Bills of lading accompanied shipments, creating delays and inefficiencies in logistics management. The growth of global trade demanded better methods for tracking and managing shipment details.

Modern communication tools sparked the shift toward electronic formats. This evolution brought forth the EDI 856 document standard in the United States, while international markets adopted the DESADV (Dispatch Advice) message format.

The automotive sector pioneered ASN adoption, quickly followed by retail industries. These early adopters recognized ASN’s value for just-in-time manufacturing, where precise delivery timing determines operational success.

Two major EDI standards emerged to guide electronic data interchange:

- UN/EDIFACT framework established global standards

- American National Standard Institute’s X12 defined EDI 856

ASN evolved beyond simple shipping notifications into sophisticated logistics tools. Modern systems enable seamless data transfer between trading partners, reducing errors in B2B deliveries. Industries handling time-sensitive items particularly benefit from ASN’s precise inventory management capabilities.

The technology proves especially valuable for complex supply chains

- Multi-party coordination

- Cross-border shipping

- Time-critical deliveries

- Inventory synchronization

What Does the Advance Shipping Notice Help to Solve?

Supply chain managers face complex logistics challenges daily. ASN addresses these operational hurdles through precise delivery information and automated documentation.

Inventory management inefficiencies plague warehouse operations. ASN eliminates these problems through real-time shipment updates, enabling strategic stock-level adjustments that prevent both stockouts and excess inventory.

Core Problems ASN Solves

1 Receiving Operation Uncertainty

- Systematic check-in procedures

- Quick order verification

- Space allocation efficiency

- Labor distribution optimization

2, Shipment Discrepancies The correlation between ASN and packing lists reduces errors between expected and received goods. This accuracy leads to

- Faster receiving cycles

- Reduced lead times

- Enhanced operational efficiency

3. Communication Gaps ASN creates direct channels between suppliers and customers. This connection enables

- Clear delivery expectations

- Stronger trading partnerships

- Streamlined operations

Why Do Buyers Request an Advance Shipping Notice?

Warehouse managers demand advanced shipping notices for precise operational control. ASN provides concrete proof of products in transit, enabling strategic receiving preparations.

1. Key Business Drivers for ASN Requirements

- Resource allocation precision

- Inventory planning accuracy

- Rapid discrepancy detection

- Administrative efficiency

- Space utilization optimization

Many distribution centers enforce strict ASN compliance. Packages arriving without proper ASN documentation face rejection at receiving docks. This policy eliminates confusion between product variants and prevents shipping errors.

2. ASN streamlines warehouse operations through

- Pre-arrival administrative processing

- Strategic storage planning

- Efficient labor scheduling

The system creates a unified data flow between trading partners. B2B operations particularly benefit – retailers pre-sell incoming inventory, preventing customer stockouts.

3. Operational Impact

- Accelerated order fulfillment

- Reduced lead times

- Real-time delivery updates

- Cross-docking capabilities

How Does ASN Benefit Suppliers?

Strategic Advantages for Suppliers

Automated Order Processing

- EDI-enabled data entry

- Real-time order tracking

- Precise shipping documentation

Risk Management ASN creates electronic audit trails for all shipments, protecting suppliers during disputes. This digital documentation expedites insurance claims for missing items.

Operational Excellence

- Accurate order processing

- Precise shipping records

- Resource optimization

Trading Partner Relations

ASN builds stronger buyer relationships through enhanced communication channels. Suppliers deliver

- Real-time shipment updates

- Proactive issue resolution

- Transparent delivery information

Business Focus

Automated shipping processes free suppliers from administrative burdens. This shift enables:

- Strategic resource allocation

- Market competitiveness

- Core business development

How are ASN and SSCCs related?

Serial Shipping Container Codes (SSCCs) power advanced shipping notice functionality through unique logistics unit identification. The 18-digit code functions like a digital license plate, connecting physical shipments to electronic documentation.

ASN and SSCC work together to bridge physical movement and digital tracking. Suppliers embed unique SSCCs for each logistics unit within the ASN, enabling precise identification of:

- Individual pallets

- Product cases

- Complete shipments

Operational Benefits

- Automated receiving processes

- Enhanced shipment tracking

- Efficient cross-docking

- Precise verification

- Strategic space management

The practical application demonstrates clear value. Buyers receiving ASN with SSCC data schedule carrier appointments and prepare resources efficiently. A single SSCC barcode scan retrieves complete shipment details from the pre-received ASN.

This integration modernizes traditional shipping methods. SSCCs link physical inventory to digital records, while ASN delivers detailed content information for each identified unit. The system reduces manual entry requirements, minimizes errors, and accelerates receiving operations.

How ASN is Used in a Real-Life Scenario?

Consider a retailer ordering products from a supplier. Once the order is packed and shipped, the supplier sends an ASN detailing:

- The shipment’s content (e.g., product types and quantities)

- Packaging details (e.g., cartons or pallets)

- Shipment tracking information

- Delivery date and time

When the shipment arrives, the retailer matches the ASN data with the physical delivery, ensuring accuracy and streamlining the receiving process.

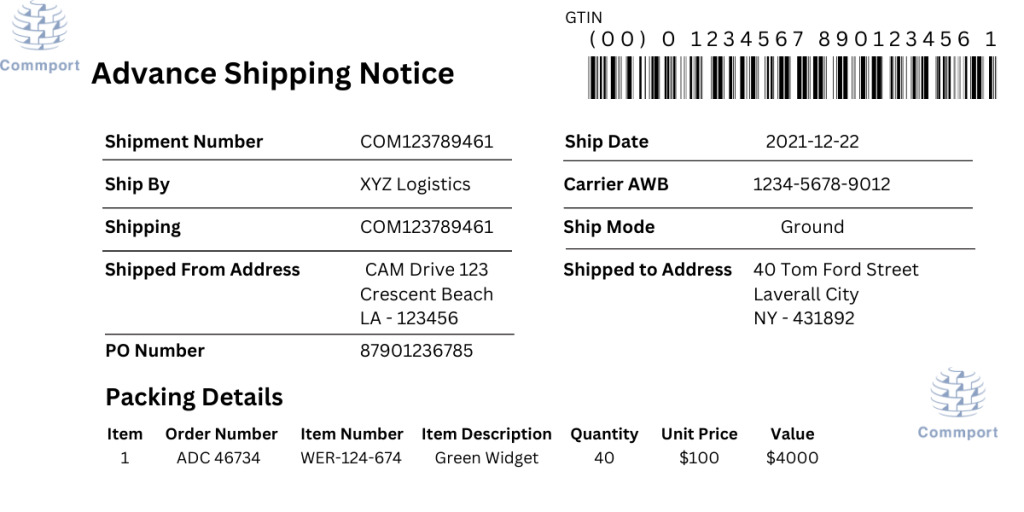

Key Components of an Advance Shipping Notice

The ASN document structure contains specific segments working together to deliver complete shipment data. The Beginning Segment for Ship Notice (BSN) forms the foundation, housing unique identifiers and transmission dates.

Document Organization

Hierarchical levels (HL) organize shipment details into clear segments:

- Shipment-level data

- Order information

- Item specifics

Core Elements

Shipment Identifiers

- Tracking numbers

- Bills of lading

- PRO numbers

Contact Details

- Shipping addresses

- Party information

Product Information

- Quantities

- SKUs

- Serial numbers

Packaging Data

- Carton contents

- Pallet configurations

Delivery Details

- Carrier information

- Expected dates

Additional Components

Reference identification (REF) segments enable supplementary tracking through

- Purchase order numbers

- Custom identifiers

Date/time references (DTM) mark key milestones

- Dispatch timing

- Expected delivery

Location Management

Warehouse segments detail

- Storage points

- Dispatch centers

The UCC128/GS1 numbering system enables end-to-end supply chain tracking.

Benefits of Using Advance Shipping Notice

1. Supply Chain Enhancement

Real-time shipment visibility powers strategic decisions. Companies optimize warehouse operations, reduce holding costs, and minimize delays.

2. Inventory Excellence

ASN strengthens stock management through:

- Precise inventory updates

- Advanced demand forecasting

- Stockout prevention

- Strategic procurement

- Product tracking optimization

3. Operational Efficiency

Warehouse teams excel with proper shipment preparation. ASN enables:

- Resource organization

- Space allocation

- Streamlined receiving

4. Process Improvement

The system delivers multiple advantages:

- Elimination of manual entry errors

- Standardized trading partner communication

- Swift dispute resolution

5. Customer Experience

ASN boosts satisfaction through precise delivery tracking and transparency. This clarity strengthens vendor-retailer relationships, driving business growth.

How Commport EDI Solutions Can Help You Automate Your Advance Ship Notices

Commport EDI Solutions powers ASN automation through specialized electronic data interchange systems. The platform converts ASNs into standardized formats for seamless trading partner processing.

Transmission Channels

Two primary methods enable ASN delivery:

- Value Added Networks (VAN) – Sort and route EDI 856 documents

- AS2 Protocol – Direct internet-based communication with encryption

Platform Capabilities

Commport’s system delivers:

- EDI ERP system integration

- Automated document exchange

- Real-time processing

- Complete audit trails

- Error detection protocols

Document Processing

The platform generates dual format outputs:

- Human-readable documents

- ERP-compatible flat files

Business Solutions

Seasonal vendors access immediate EDI capabilities through Commport’s outsourcing services. The system manages:

- Trading partner connections

- Retail communications

- Relationship maintenance

Cloud Implementation

Modern cloud architecture enables ASN exchange through standard internet connections. This approach delivers:

- Simple deployment

- Automated validation

- Error reduction

- Processing accuracy

Conclusion

Advance Shipping Notices (ASNs) are essential for modern supply chains, offering transparency, accuracy, and efficiency. By leveraging ASNs, businesses can enhance communication, streamline operations, and build stronger relationships with trading partners.

Commport Communications provides comprehensive EDI solutions to help businesses automate ASNs and achieve seamless supply chain integration. Partner with Commport to unlock the full potential of ASNs and take your operations to the next level.

Need Help? Download: EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Commport EDI Solutions

Frequently Asked Questions

An Advanced Shipping Notice is an electronic document sent by suppliers to buyers before a shipment leaves the warehouse. It contains detailed information about the upcoming delivery, including order numbers, product descriptions, quantities, and expected delivery dates.

The shipper or supplier sending the goods is responsible for generating and sending the ASN to the buyer. This electronic document originates from the seller’s end of the supply chain, providing crucial shipment details to the receiving party.

While both provide shipment details, an ASN is sent electronically before the shipment arrives and includes more comprehensive information. Unlike a packing list that travels with the shipment, an ASN reaches the destination’s receiving operations well in advance, allowing for better preparation and planning.

The best time to send an ASN is as soon as the shipment is processed and tracking information is available. Typically, this occurs just before or immediately after the shipment leaves the supplier’s facility, ensuring the buyer has ample time to prepare for the incoming delivery.

Implementing ASN can lead to significant benefits, including reduced receiving costs (up to 40%), improved inventory management, enhanced supply chain visibility, streamlined warehouse operations, and stronger partnerships between trading partners. It also enables faster order fulfillment and improves overall operational efficiency.