Introduction

Managing inventory effectively is a critical aspect of supply chain operations. Yet, despite meticulous planning, businesses often encounter backorders. Backorders occur when customer demand exceeds the available inventory, leading to delayed fulfillment of orders.

While backorders can be seen as a signal of strong demand, they also pose challenges to supply chain efficiency, customer satisfaction, and brand reputation. By understanding this complex phenomenon, businesses can develop more robust strategies to handle unexpected challenges and maintain customer loyalty.

Key Takeaways

- EDI simplifies backorder management by automating communication between suppliers and retailers.

- It enables real-time updates on inventory levels and expected delivery dates, reducing delays.

- Common EDI transactions like EDI 855 (Purchase Order Acknowledgment) and EDI 856 (Advance Shipping Notice) streamline backorder tracking.

- Automated processes minimize manual errors, ensuring accurate and efficient handling of backorders.

- Managing backorders with EDI improves customer satisfaction by providing timely and transparent updates.

Define Backorder

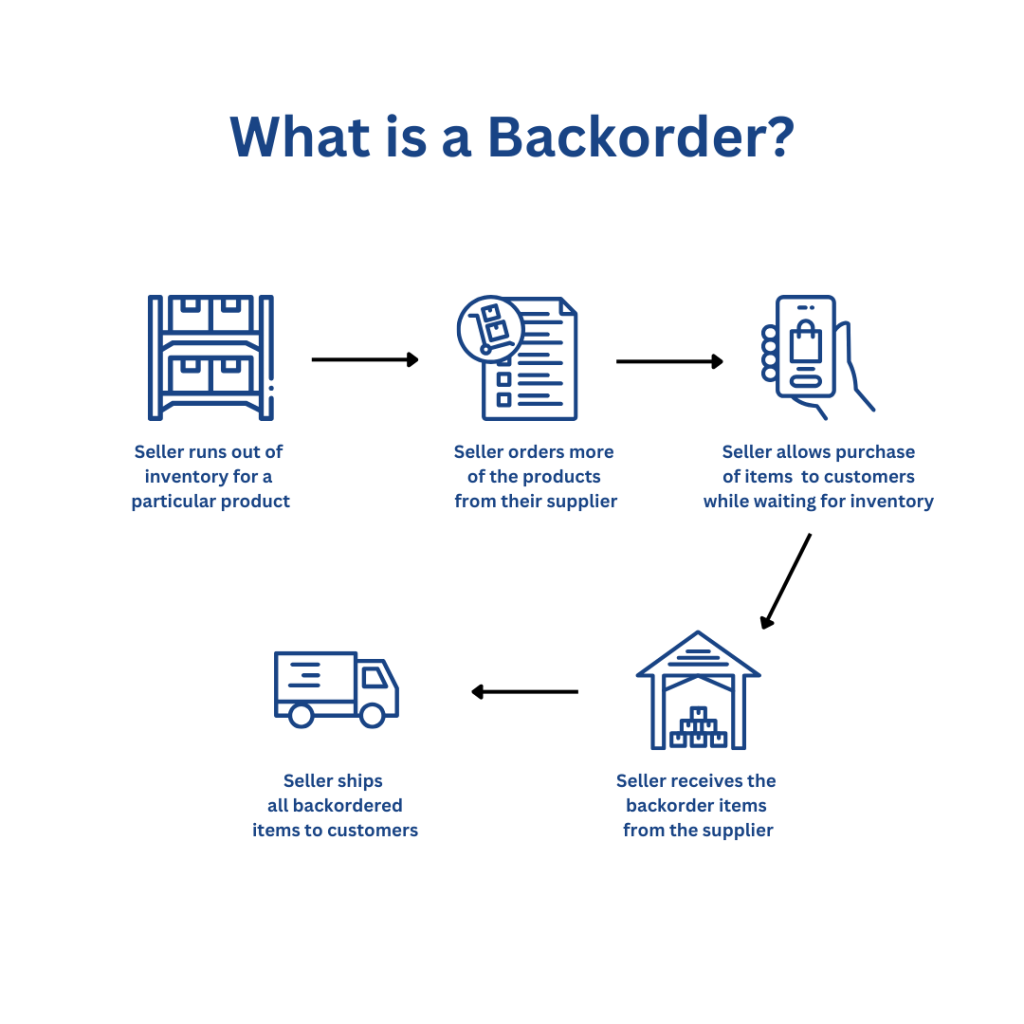

A backorder occurs when a customer places an order for a product that is currently unavailable in inventory but is expected to be replenished in the future. The business accepts the order despite the unavailability of stock, with a promise to fulfill it as soon as the inventory is restocked.

Key Characteristics of Backorders:

- The product is confirmed as available soon

- Customers are willing to wait for the product

- The sale is not canceled but delayed

- The company commits to fulfilling the order

Example of a Backorder

Imagine a retailer selling a popular gaming console during the holiday season. Due to unexpectedly high demand, the entire inventory sells out within a week. However, the manufacturer has confirmed a new shipment in two weeks. The retailer allows customers to place orders despite the unavailability of stock, promising delivery after the new inventory arrives. These orders are categorized as backorders.

What Causes Backorders?

Several factors can lead to backorders. Here are the most common causes:

- Surge in Demand

Unexpected spikes in demand, often driven by seasonal trends, viral marketing campaigns, or unanticipated market interest, can deplete inventory faster than anticipated.

- Supply Chain Disruptions

Delays in production, transportation bottlenecks, or supplier issues can slow down the replenishment of stock, creating a gap between demand and availability.

- Inaccurate Inventory Forecasting

Poor demand forecasting or miscalculations in inventory management can result in stock shortages, leading to backorders.

- Limited Production Capacity

Manufacturers with constrained production capacity may struggle to meet increased demand, resulting in delays.

- Raw Material Shortages

A shortage of raw materials or components required for manufacturing can halt or delay production.

- Custom or Specialized Products

Products that are made-to-order or highly customized often require longer lead times, resulting in backorders.

Backorder Vs Out of Stock – The Key Difference

Feature |

Backorder |

Out of Stock |

|---|---|---|

| Definition | The product is unavailable but can still be ordered for later delivery. | The product is unavailable and cannot be ordered. |

| Customer Experience | Customers can place orders with an extended delivery time. | Customers cannot place orders. |

| Replenishment Status | Stock will be replenished soon. | The stock replenishment timeline is unknown or indefinite. |

| Impact on Sales | Sales are delayed but not lost. | Potential loss of sales and revenue. |

How Backorders Affect Supply Chains?

Backorders can have both positive and negative impacts on supply chains:

Positive Impacts

- Indicates Strong Demand: Backorders can signal that a product is popular and in high demand, helping businesses plan future inventory strategies.

- Customer Loyalty Opportunities: When handled well, customers may remain loyal despite delays.

Negative Impacts

- Strains on Logistics: Managing backorders increases operational complexity, especially in tracking and prioritizing orders.

- Customer Dissatisfaction: Prolonged delays can lead to frustration, resulting in negative reviews or loss of future sales.

- Higher Costs: Additional handling, expedited shipping, or production adjustments can increase costs.

How to Manage Backorders Using EDI?

Electronic Data Interchange (EDI) helps streamline the backorder management process.

Here’s a step-by-step guide to managing backorders effectively using an EDI solution:

- Order Placement

The customer places an order for an out-of-stock item. Through EDI, the order is instantly transmitted to the supplier or manufacturer.

- Inventory Status Updates

Using EDI transaction codes like 846 (Inventory Inquiry/Advice), businesses can monitor real-time stock availability and inform customers about order status.

- Order Confirmation

An EDI 855 (Purchase Order Acknowledgment) is sent to confirm the order, along with an estimated delivery date.

- Production/Restocking

The supplier or manufacturer replenishes inventory, keeping the business updated with an EDI 856 (Advance Shipping Notice) once the stock is ready for shipment.

- Fulfillment and Shipping

When the backordered item is available, the business fulfills the order and sends an EDI 810 (Invoice) to the customer along with shipping details.

- Post-Delivery Updates

Using EDI 824 (Application Advice), businesses can handle feedback or discrepancies related to the backorder, ensuring smooth resolution.

Advantages and Disadvantages of Selling on Backorders

Advantages

- Retain Sales: Allows businesses to capture sales even when stock is unavailable.

- Improved Cash Flow: Customers may prepay for backorders, providing immediate cash inflow.

- Demand Insights: Backorders help businesses gauge product popularity and refine inventory planning.

Disadvantages

- Customer Dissatisfaction: Delays in delivery can frustrate customers and harm brand reputation.

- Operational Challenges: Managing backorders adds complexity to supply chain operations.

- Increased Costs: Additional communication, expedited shipping, and restocking efforts can drive up costs.

Tips to Minimize Backorders

- Enhance Inventory Forecasting: Use advanced analytics to predict demand accurately and adjust stock levels accordingly.

- Diversify Suppliers: Partner with multiple suppliers to reduce the risk of supply chain disruptions.

- Implement EDI Solutions: Streamline communication with suppliers and automate inventory updates for better visibility.

- Increase Safety Stock: Maintain a buffer stock of high-demand items to reduce the likelihood of shortages.

- Optimize Lead Times: Work closely with suppliers to shorten lead times and improve responsiveness.

Conclusion

Backorders are an inevitable part of inventory management, especially in a dynamic marketplace. While they can signal strong demand, poor management can lead to customer dissatisfaction and operational inefficiencies. By leveraging modern technologies like EDI, businesses can manage backorders effectively, ensuring timely communication and fulfillment.

By understanding the causes, benefits, and challenges of backorders, businesses can turn them into opportunities for growth while minimizing their negative impacts. With a proactive approach and the right tools, backorders can be a manageable aspect of supply chain operations.

Need Help? Download: EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Commport EDI Solutions

Frequently Asked Questions

Accurate forecasting helps maintain optimal stock levels, reducing the risk of backorders and improving supply chain efficiency.

Backorders help retain sales during stockouts, provide demand insights, and maintain customer loyalty.

EDI automates the communication process between suppliers and retailers, ensuring real-time inventory updates and efficient backorder handling.

Yes, if not managed properly, backorders can lead to delays and frustration, impacting customer satisfaction.

Backorders can still be placed with a promise of future delivery, while “out of stock” indicates that the product is unavailable for purchase.